- Abrasive Blasting. A process for cleaning or finishing by a means of an abrasive directed at the work piece at differing pressures & velocities. Grits available range from extremely fine (plastic media) to very course (aluminum oxide). A grit for almost any application.

- Activation. Elimination of a passive condition on a surface

- Activity (Ion). The ion concentration corrected for deviations from ideal behavior. Concentration multiplied by activity coefficient.

- Addition Agent. A material added in small quantities to a solution to modify its characteristics. It is usually added to a plating solution for the purpose of modifying the character of a deposit.

- Adhesion. The attractive force that exists between an electrodeposit and its substrate that can be measured as the force required to separate an electrodeposit and its substrate.

- Amorphous. Non-crystalline, or devoid of regular structure.

- Ampere. The current that will deposit silver at the rate of 0.0011180 g per sec. Current flowing at the rate of 1 coulomb per sec.

- Angstrom Unit (A). x 10-8 cm.

- Anion. A negatively charged ion.

- Anode. The electrode in electrolysis, at which negative ions are discharged, positive ions are formed, or other oxidizing reactions occur.

- Anode Efficiency. Current efficiency of a specified anodic process.

- Anode Film.

- (1) The layer of solution in contact with the anode that differs in composition from that of the bulk of the solution.

- (2) The outer layer of the anode itself consisting of oxidation or reaction products of the anode metal.

- Anode Polarization. See Polarization.

- Anodic Coating. A protective, decorative, or functional coating, formed by conversion of the surface of a metal in an electrolytic oxidation process.

- Anodizing. An electrolytic oxidation process in which the surface of a metal, when anodic, is converted to a coating having desirable protective, decorative, or functional properties.

- Anolyte. The portion of electrolyte in the vicinity of the anode; in a divided cell, the portion of electrolyte on the anode side of the diaphragm.

- Anti-Pitting Agent. An addition agent for the specific purpose of preventing gas pits in a deposit.

- Automatic Machine (or Conveyor). A machine for mechanically processing parts through treatment cycles, such as cleaning, anodizing, or plating.

- Automatic Plating.

- (1) Full. Plating in which the cathodes are automatically conveyed through successive cleaning and plating tanks.

- (2) Semi. Plating in which the cathodes are conveyed automatically through only one plating tank.

- Back EMF (Electromotive Force). The potential set up in an electrolytic cell that opposes the flow of current, caused by such factors as concentration polarization and electrode films. See EMF.

- Barrel Burnishing. The smoothing of surfaces by means of tumbling the work in an rotating barrels in an the presence of metallic or ceramic shot, and in an the absence of abrasive. In an ball burnishing, the shot consists of hardened steel balls.

- Barrel Finishing (or Tumbling). Bulk processing in a barrel, in either the presence or absence of abrasives or burnishing shot, for the purpose of improving the surface finish.

- Barrel Plating (or Cleaning). Plating or cleaning in which the work is processed in bulk in a rotating container.

- Base Metal. A metal that readily oxidizes or dissolves to form ions. The opposite of noble metal.

- Basis Metal (or Material). Material upon which coatings are deposited.

- Bipolar Electrode. An electrode that is not directly connected to the power supply but is so placed in the solution between the anode and the cathode that the part nearest the anode becomes cathodic and the part nearest the cathode becomes anodic.

- Blue Dip. A solution, once widely used, containing a mercury compound used to deposit mercury upon a metal by immersion, usually prior to silver plating.

- Bright Dip (Non electrolytic). A solution used to produce a bright surface on a metal.

- Bright Plating. A process that produces an electrodeposit having a high degree of specular reflectance in the as-plated condition.

- Bright Plating Range. The range of current densities within which a given plating solution produces a bright plate.

- Bright-Throwing Power. The measure of the ability of a plating solution or a specified set of plating conditions to deposit uniformly bright electroplate upon an irregularly shaped cathode.

- Brightener. An addition agent that leads to the formation of a bright plate, or that improves the brightness of the deposit.

- Brush Plating. A method of plating in which the plating solution is applied with a pad or brush within which is an anode, and which is moved over the cathode to be plated.

- Buffer. A compound or mixture that, when contained in a solution, causes the solution to resist change in pH. Each buffer has a characteristic limited range of pH over which it is effective.

- Buffing. The smoothing of a surface by means of a rotating flexible wheel to the surface of which fine, abrasive particles are applied in a liquid suspension, paste, or grease stick form.

- Building Up. Electroplating for the purpose of increasing the dimensions of an article.

- Burnishing. The smoothing of surfaces by rubbing, accomplished chiefly by the movement rather than the removal of the surface layer.

- Burnt Deposit. A rough, non-coherent or otherwise unsatisfactory deposit produced by the application of an excessive current density and usually containing oxides or other inclusions.

- Bus (Bus Bar). A rigid conducting section, for carrying current to the anode and cathode bars.

- Butler Finish. A finish composed of fine, uniformly-distributed parallel lines, having a characteristic luster usually produced with rotating wire brushes or cloth wheels with applied abrasives.

- Calomel Half Cell (Calomel Electrode). An electrode in contact with a solution of potassium chloride of specified concentration that is saturated with mercurious chloride (calomel).

- Cataphoresis. See Electrophoresis.

- Cathode. The electrode in an electrolysis at which positive ions are discharged, negative ions are formed, or other reducing actions occur.

- Cathode Efficiency. The current efficiency of a specified cathodic process.

- Cathode Film. The layer of solution in an contact with the cathode that differs in an composition from that of the bulk of the solution.

- Cathodic polarization. See Polarization.

- Catholyte. The portion of the electrolyte in an the vicinity of the cathode; in an a divided cell the portion on the cathode side of the diaphragm.

- Cation. A positively-charged ion.

- Chelate Compound. A compound in which the metal is contained as an integral part of a ring structure and is not readily ionized.

- Chelating Agent. A compound capable of forming a chelate compound with a metal ion. See Chelate Compound.

- Chemical Polishing. The improvement in an smoothness of a metal by simple immersion in an a suitable solution. See Bright Dip (Nonelectrolytic).

- Cleaning. The removal of grease or other foreign material from a surface.

- Alkaline Cleaning. Cleaning by means of alkaline solutions.

- Anodic or Reverse Cleaning. Electrolytic cleaning in which the work is the anode.

- Cathodic or Direct Cleaning. Electrolytic cleaning in which the work is the cathode.

- Diphase Cleaning. Cleaning by means of a solution that contains a solvent layer and an aqueous layer. Cleaning is effected both by solvent and emulsifying action.

- Direct Current Cleaning. See Cathodic or Direct Cleaning.

- Electrolytic Cleansing. Alkaline cleaning in an which a current is passed through the solution, the work being one of the electrodes.

- Immersion. See Soak Cleaning.

- Reverse Current Cleaning. See Anodic or Reverse Cleaning.

- Soak Cleaning. Cleaning by immersion without the use of current, usually in an alkaline solution.

- Solvent Cleaning. Cleaning by means of organic solvents.

- Spray Cleaning. Cleaning by mean of spraying.

- Ultrasonic Cleaning. Cleaning by any chemical means aided by ultrasonic energy.

- Colloidal Particle. An electrically-charged particle, generally smaller in size than 200 mµ, dispersed in a second continuous phase.

- Coloring.

- (1) The production of desired colors on metal surfaces by appropriate chemical or electrolytical action.

- (2) Light buffing of metal surfaces for the purpose of producing a high luster. Caged “Color buffing.”

- Complex Ion. An ion composed of two or more ions or radicals, both of which are capable of independent existence; for example, cuprocyanide (Cu(CN)2)-.

- Complexing Agent. A compound that will combine with metallic ions to form complex ions. See Complex Ion.

- Composite Plate. An electrodeposit consisting of two or more layers of metal deposited successively.

- Concentration Polarization. That part of the total polarization that is caused by changes in the activity of the potential-determining components of the electrolyte.

- Conductance. The capacity of a medium, usually expressed in mhos, for transmitting electric current. The reciprocal of resistance.

- Conducting Salt. A salt added to the solution in an order to increase its conductivity.

- Conductivity / Specific Conductance. The current transferred across unit area per unit potential gradient. In the metric system, K = amperes per sq cm divided by volts per cm. The reciprocal of resistivity.

- Contact Plating. Deposition of a metal by the use of an internal source of current by immersion of the work in a solution in contact with another metal.

- Contact Potential. The potential difference at the junction of two dissimilar substances.

- Conversion Coating. A coating produced by chemical or electrochemical treatment of a metal solution that gives a superficial layer containing a compound of the metal. For example: chromate coatings on zinc and cadmium, oxide coating on steel.

- Corrosion.

- (1) Gradual solution or oxidation of a metal.

- (2) Solution of anode metal by the electrochemical action in the plating cell.

- Coulomb.

- (1) The quantity of electricity that is transmitted through an electric circuit in 1 second when the current in the circuit is 1 amp.

- (2) The quantity of electricity that will deposit 0.0011180 g of silver.

- Coulometer. An electrolytic cell arranged to measure the quantity of electricity by the chemical reaction produced in accordance with Faraday’s law.

- Covering Power. The ability of a plating solution under a set of specified plating conditions to deposit metal on the surfaces of recesses or deep holes. (To be distinguished from throwing power.)

- Critical Current Density. A current density above which a new and sometimes undesirable reaction occurs.

- Current Density (cd). Current per unit area.

- Current Efficiency. The proportion, usually expressed as a percentage, of the current that is effective in carrying out a specified process in accordance with Faraday’s Law.

- Cutting Down. Polishing or buffing for the purpose of removing roughness or irregularities.

- Deburring. The removal of burrs, sharp edges or fins by mechanical, chemical, or electrochemical means.

- Decomposition Potential. The minimum potential, exclusive of IR drop, at which an electrochemical process can take place at an appreciable rate.

- Degreasing. The removal of grease and oils from a surface.

- Solvent Degreasing. Degreasing by immersion in an liquid organic solvent.

- Vapor Degreasing. Degreasing by solvent vapors condensing on the parts being cleaned.

- Deionization. The removal of ions from a solution by ion exchange.

- Depolarization. A decrease in the polarization of an electrode at a specified current density.

- Depolarizer. A substance or a means that produces depolarization.

- Detergent. A surface active agent that possess the ability to clean soiled surfaces.

- Anionic Detergent. A detergent that produces aggregates of negatively-charged ions with colloidal properties.

- Cationic Detergent. A detergent that produces aggregates of positively-charged ions with colloidal properties.

- Nonionic Detergent. A detergent that produces aggregates of electrically-neutral molecules with colloidal properties.

- Diaphragm. A porous or permeable membrane separating anode and cathode compartments of an electrolytic cell from each other or from an intermediate compartment.

- Diffusion Coating. An alloy coating produced by applying heat to one or more coatings deposited on a basis metal

- Dispersing Agent. A substance that increases the stability of a suspension by retarding the flocculation of such particles.

- Divided Cell. A cell containing a diaphragm or other means for physically separating the anolyte from the catholyte.

- Double Salt. A compound of two salts that crystallize together in a definite proportion.

- Drag-In. The water or solution that adheres to the objects introduced into a bath.

- Drag-Out. The solution that adheres to the objects removed from a bath.

- Dummy (or Dummy Cathode). A cathode in a plating solution that is not to be made use of after plating. Often used for removal or decomposition of impurities.

- Electrochemical Equivalent. The weight of an element, compound, radical, or ion involved in a specified electrochemical reaction during the passage of unit quantity of electricity, such as a Faraday, ampere-hour, or coulomb.

- Electrochemistry. The branch of science and technology which deals with transformations between chemical and electrical energy.

- Electrode. A conductor through which current enters or leaves an electrolytic cell, at which there is a charge from conduction by electrons to conduction by charged particles of matter, or vice versa.

- Electrodeposition. The process of depositing a substance upon an electrode by electrolysis. See Electroforming, Electroplating, Electrorefining, and Electrowinning.

- Electrode Potential (E.P.). The difference in an potential between an electrode and the immediately adjacent electrolyte referred to some standard electrode potential as zero.

- Dynamic E.P. The electrode potential measured when current is passing between the electrode and the electrolyte.

- Equilibrium E.P. A static electrode potential when the electrode and the electrolyte are in equilibrium with respect to a specified electrochemical reaction.

- Static E.P. The electrode potential measured when no net current is flowing between the electrode and the electrolyte.

- Standard E.P. An equilibrium electrode potential for an electrode in contact with an electrolyte in which all of the components of a specified chemical reaction are in their standard states. The standard state for an ionic constituent is unit ion activity.

- Electroforming. The production or reproduction of articles by electrodeposition upon a mandrel or mold that is subsequently separated from the deposit.

- Electrogalvanizing. Electrodeposition of zinc coatings.

- Electroless Plating. Deposition of a metallic coating by a controlled chemical reduction that is catalyzed by the metal or alloy being deposited.

- Electrolyte.

- (1) A conducting medium in which the flow of current is accompanied by a movement of matter. Most often an aqueous solution of acids, bases, or salts, but includes many other media, such as fused salts, ionized gases, some solids, etc.

- (2) A substance that is capable of forming a conducting liquid medium when dissolved or melted.

- Electrolysis. Production of chemical changes by the passage of current through an electrolyte.

- Electrolytic Cell. A unit apparatus in which electrochemical reactions are produced by applying electrical energy, or which supplies electrical energy as a result of chemical reactions, and which includes two or more electrodes and one or more electrolytes contained in a suitable vessel.

- Electromotive Series. A table that lists in an order the standard electrode potentials of specified chemical reactions.

- Electrophoresis. The movement of colloidal particles produced by the application of an electric potential.

- Electroplating. The electrodeposition of an adherent metallic coating upon an electrode for the purpose of securing a surface with properties or dimensions different from those of the basis metal.

- Electropolishing. The improvement in surface finish of a metal effected by making it anodic in an appropriate solution.

- Electrorefining. The process of anodically dissolving a metal from an impure anode and depositing it cathodically in a purer form.

- Electrotyping. The production of printing plates by electroforming.

- Electrowinning. The production of metals by electrolysis with insoluble anodes in solutions derived from ores or other materials.

- Embrittlement, Hydrogen. See Hydrogen Embrittlement.

- EMF (Electromotive Force). An electrical potential.

- Emulsion. A suspension of small droplets of one liquid in another in which it is insoluble. For the formation of a stable emulsion, an emulsifying agent must usually be present.

- Emulsifying Agent. A substance that increases the stability of an emulsion.

- Energy Efficiency. The product of the current efficiency and the voltage efficiency for a specified electrochemical process.

- Equivalent Conductivity. In an electrolyte, the conductivity of the solution divided by the number of equivalents of conducting solute per unit volume; that is, the conductivity divided by the normality of the solution.

- Etch.

- (n) A roughened surface produced by a chemical or electrochemical means.

- (v) To dissolve unevenly (or uniformly) a part of the surface of a metal.

- Faraday. The number of coulombs (96,490) required for an electrochemical reaction involving one chemical equivalent.

- Ferritic Stainless Steel. Ferritic stainless steels are chromium alloys with a low carbon content. They are magnetic and have a good ductility, plus resistance to corrosion and oxidation (they are especially resistant to stress corrosion cracking).

- Filter Aid. An inert, insoluble material, more or less finely divided, used as a filter medium or to assist in a filtration by preventing excessive packing of the filter cake.

- Flash (or Flash Plate). A thin electrodeposit, less than 0.1 mil. See Strike.

- Flocculate. To aggregate into larger particles, or to increase in size to the point where precipitation occurs.

- Formula Weight. The weight, in an grams, pounds, or other units, obtained by adding the atomic weights of all elemental constituents in an a chemical formula.

- Free Cyanide.

- (1) True. The actual concentration of cyanide radical, or equivalent alkali cyanide, not combined in an complex ions with metals in a solution.

- (2) Calculated. The concentration of cyanide, or alkali cyanide, present in a solution in excess of that calculated as necessary to form a specified complex ion with a metal or metals present in a solution.

- (3) Analytical free cyanide content of a solution, as determined by a specified analytical method.

- Note: The true value of free cyanide is rarely known with certainty and is therefore usually only dealt with in an discussions of theory. The calculated or analytical value is usually used in an practice.

- Galvanic Cell. An electrolytic cell capable of producing electrical energy by electrochemical action.

- Galvanic Series. A list of metals and alloys arranged according to their relative Potentials in a given environment. See Electromotive Series.

- Galvanizing. Application of a coating of zinc.

- Gassing. The evolution of gasses from one or more of the electrodes during electrolysis.

- Glass Electrode. A half cell in which the potential measurements are made through a glass membrane.

- Grinding. The removal of metal by means of a rotating rigid wheel containing abrasive.

- Grit Blasting. Abrasive blasting with small irregular pieces of steel or malleable cast iron.

- Half Cell. An electrode immersed in a suitable electrolyte. It may be designed to yield a known constant potential, in which case unknown potentials may be measured against it; for example, the calomel half cell.

- Hard Chromium. Chromium plated for engineering rather than decorative applications. Not necessarily harder than the latter.

- Haring Cell. A rectangular box of nonconducting material, with principal and auxiliary electrodes so arranged as to permit estimation of throwing power of electrode polarizations and potentials between them.

- High Lights. Those portions of a metal article most exposed to buffing or operations and hence having the highest luster.

- Hull Cell. A trapezoidal box of nonconducting material with electrodes arranged to permit observation of cathodic or anodic effects over a wide range of current densities.

- Hydrogen Embrittlement. Embrittlement of a metal or alloy caused by absorption of hydrogen during a pickling, cleaning, or plating process.

- Hydrogen Overvoltage. Overvoltage associated with the liberation of hydrogen.

- Hydrophilic.

- (1) Tending to absorb water.

- (2) Tending to concentrate in the aqueous phase.

- Hydrophobic.

- (1) Tending to repel water.

- (2) Lacking affinity for water.

- Immersion Plate. A metallic deposit produced by a displacement reaction in which one metal displaces another from a solution. For example: Fe+Cu++ –> Cu+Fe++ (copper replacing iron).

- Indicator (pH). A substance that changes color when the pH of the medium is changed. In the case of most useful indicators, the pH range within which the color changes is narrow.

- Inert Anode. An anode that is insoluble in the electrolyte under the conditions prevailing in an the electrolysis.

- Inhibitor. A substance used to reduce the rate of a chemical or electrochemical reaction, commonly corrosion or pickling.

- Interfacial Tension. The contractile force of an interface between two phases. See Surface Tension.

- Ion. An charged portion of matter of atomic or molecular dimensions.

- Ion Exchange. An exchange of ions between a solution and a solid. In practice, most commonly effected by ion exchange resins.

- IR Drop. The voltage across a resistance in accordance with Ohm’s Law: E = IR where: E = potential (voltage), I = current, and R = resistance.

- Karat. A twenty-fourth part by weight. Thus, 18-karat gold is 18/24 pure.

- Lapping. Rubbing two surfaces together, with or without abrasives, for the purpose of obtaining extreme dimensional accuracy or superior surface finish.

- Leveling Action. The ability of a plating solution to produce a surface smoother than that of the substrate.

- Limiting Current Density.

- (1) Cathodic. The maximum current density at which satisfactory deposits can be obtained.

- (2) Anodic. The maximum current density at which the anode behaves normally, without excessive polarization.

- Mat Finish (or Matte Finish). A dull finish.

- Matrix. A form used as a cathode in electroforming; a mold or mandrel.

- Metal Distribution Ratio. The ratio of the thicknesses of metal upon two specified areas of a cathode. See Throwing Power.

- Metallizing.

- (1) The application of an electrically conductive metallic layer to the surface of nonconductors.

- (2) The application of metallic coatings by nonelectrolytic procedures such as spraying of molten metal and deposition from the vapor phase.

- Microinch. One millionth of an inch (0.000001 in). Equal to 0.001 mil.

- Micron (µ). One millionth of a meter (0.001 mm).

- Microthrowing Power. The ability of a plating solution or a specified set of plating conditions to deposit metal in pores or scratches.

- Mil. One thousandth of an inch, (0.001 in). Equal to 25.4 µ.

- Mill Scale. The heavy oxide layer formed during hot fabrication or heat treatment of metals.

- Motor-Generator (MG Set).

- (1) A machine that consists of one or more motors mechanically coupled to one or more generators.

- (2) In plating, such a machine in which the generator delivers DC of appropriate amperage and voltage.

- Orange Peel. A finish resembling the dimpled appearance of an orange peel.

- Overvoltage. The irreversible excess of potential required for an electrochemical reaction to proceed actively at a specified electrode, over and above the reversible potential characteristics of that reaction.

- Oxidation. A reaction in which electrons are removed from a reactant. Sometimes, more specifically, the combination of a reactant with oxygen.

- Oxidizing Agent. A compound that causes oxidation, thereby itself becoming reduced.

- Noble Metal. A metal that does not readily tend to furnish ions, and therefore does not dissolve readily, nor easily enter into such reactions as oxidations, etc. The opposite of base metal.

- Note: Since there is no agreement over the sign of electrode potentials the words noble and base are often preferred because they are unambiguous.

- Nodule. A rounded projection formed on a cathode during electrodeposition.

- pH. A unit of measure depicting the hydrogen concentration of a solution on a scale of 1 to 14, where 7 is neutral, <7 acidic, and >7 basic.

- Passivity. The condition of a metal that retards its normal reaction in a specified environment, and associated with the assumption of a potential more noble than its normal potential.

- Peeling. The detachment or partial detachment of an electrodeposited coating from a basis metal or undercoat.

- Periodic Reverse Plating. A method of plating in which the current is reversed periodically. The cycles are usually no longer than a few minutes and may be much less.

- Pickle. An acid solution used to remove oxides or other compounds from the surface of a metal by chemical or electrochemical action.

- Pickling. The removal of oxides or other compounds from a metal surface by means of a pickle.

- Pit. A small depression or cavity produced in a metal surface during electrodeposition or by corrosion.

- Plastisol. A mixture of resins, plasticizers, and other minor additives (such as pigments, etc.) that can be converted to a continuous film by the application of heat. Distinct from baking enamels, etc., in that substantially all the original mixture becomes a part of the film; there is no significant evaporation of solvent. The films are usually much thicker than obtainable from coatings which depend on the evaporation of a volatile solvent.

- Plating Range. The current density range over which a satisfactory electroplate can be deposited.

- Polarization. The change in the potential of an electrode during electrolysis, such that the potential of an anode always becomes more noble and that of a cathode becomes less noble than their respective static potentials. Equal to the difference between the static potential and the dynamic potential.

- Polarizer. A substance or a means that produces or increases polarization.

- Polishing. The smoothing of a metal surface by means of the action of abrasive particles attached by adhesive to the surface of wheels or endless belts usually driven at a high speed.

- Primary Current Distribution. The distribution of the current over the surface of an electrode in the absence of polarization.

- Rack, Plating. A frame for suspending and carrying current to articles during plating and related operations.

- Rectification. The conversion of alternating into direct current.

- Rectifier. A device that converts alternating into direct current by virtue of a characteristic permitting appreciable flow of current in an only one direction.

- Reducing Agent. A compound that causes reduction, thereby itself becoming oxidized.

- Reduction. A reaction in which electrons are added to a reactant. More specifically, the addition of hydrogen or the abstraction of oxygen. Such a reaction takes place, for example, at the cathode in an electrolysis.

- Relieving. The removal of material from selected portions of a colored metal surface by mechanical means, to achieve a multi-colored effect

- Resist.

- (1) A material applied to a part of a cathode or plating rack to render the surface nonconductive.

- (2) A material applied to a part of the surface of an article to prevent reaction of metal from that area during chemical or electrochemical processes.

- Ripple (DC). Regular modulations in the DC output wave of a rectifier unit, or a motor-generator set, originating from the harmonics of the AC input system in the case of a rectifier, or from the harmonics of the induced voltage of a motor generator set.

- Robber. See Thief.

- Sacrificial Protection. The form of corrosion protection wherein one metal corrodes in preference to another, thereby protecting the latter from corrosion.

- Sand Blasting. Abrasive blasting with sand.

- Saponification. The alkaline hydrolysis of fats whereby a soap is formed; more generally, the hydrolysis of an ester by an alkali with the formation of an alcohol and a salt of the acid portion.

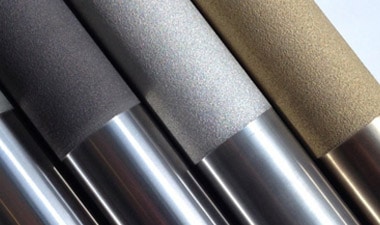

- Satin Finish. A surface finish that behaves as a diffuse reflector and which is lustrous but not mirrorlike.

- Scale. An adherent oxide coating that is thicker than the superficial film referred to as tarnish.

- Sealing of Anodic Coating. A process which, by absorption, chemical reaction, or other mechanism, increases the resistance of an anodic coating to staining and corrosion, improves the durability of colors produced in the coating, or imparts other desirable properties.

- Sequestering Agent. An agent that forms soluble complex ions with, or sequesters, a simple ion, thereby suppressing the activity of that ion. Thus, in water treatment, the effects of hardness can be suppressed by adding agents to sequester calcium and magnesium. See Chelating Agent.

- Shield.

- (n) A nonconducting medium for altering the current distribution on an anode or cathode.

- (v) To alter the normal current distribution on an anode or cathode by the interposition of a nonconductor.

- Slurry. A suspension of solids in water.

- Spotting out. The delayed appearance of spots and blemishes on plated or finished surfaces.

- Stalagmometer. An apparatus for determining surface tension. The mass of a drop of a liquid is measured by weighing a known number of drops or by counting the number of drops obtained from a given volume of the liquid.

- Stop-Off. See Resist.

- Stopping Off. The application of a resist to any part of an electrode (cathode, anode, or rack).

- Stray current. Current through paths other than the intended circuit, such as through heating coils or the tank.

- Strike.

- (1) (n) A thin film of metal to be followed by other coatings.

- (2) (n) A solution used to deposit a strike.

- (3) (v) To plate for a short time, usually at a high initial current density.

- (4) (v) To remove a coating from the basis metal or undercoat

- Strip. A process or solution used for the removal of a coating from a basis metal or an undercoat

- Substrate. See Basis Metal (or Material).

- Superimposed AC. A form of current in which an alternating current component is superimposed on the direct plating current.

- Surface Active Agent (Surfactant). A soluble or colloidal substance having the property of affecting markedly the surface energy of solutions even when present in very low concentration.

- Surface Tension. That property, due to molecular forces, that exists in the surface film of all liquids and tends to prevent the liquid from spreading.

- Tank Voltage. The total voltage between the anode and cathode of a plating bath or electrolytic cell during electrolysis. It is equal to the sum of: (1) the equilibrium reaction potential, (2) the IR drop, and (3) the electrode potentials.

- Tarnish.

- (1) The dulling, staining, or discoloration of metals due to superficial corrosion.

- (2) The film so formed.

- Thief. An auxiliary cathode so placed as to divert to itself some current from portions of the work which would otherwise receive too high a current density.

- Throwing Power. The improvement of the coating (usually metal) distribution over the primary current distribution on an electrode (usually cathode) in a given solution under specified conditions. The term may also be used for anodic processes for which the definition is analogous.

- Total Cyanide. The total content of cyanide expressed as the radical CN-, or alkali cyanide, whether present as simple or complex ions. The sum of both the combined and free cyanide content of a solution.

- Transference (or Transport, or Migration). The movement of ions through the electrolyte associated with the passage of the electric current.

- Transference Number (or Transport Number). The proportion of the total current carried by the ions of a given kind.

- Trees. Branched or irregular projections formed on a cathode during electrodeposition, especially at edges and other high-current-density areas.

- Tripoli. Friable and dustlike silica used as an abrasive.

- Tumbling. See Barrel Finishing.

- Voltage Efficiency. The ratio, usually expressed as a percentage, of the equilibrium reaction potential in a given electrochemical process to the bath voltage.

- Water Break. The appearance of a discontinuous film of water on a surface signifying nonuniform wetting and usually associated with a surface contamination.

- Wet Blasting. A process for cleaning or finishing by means of a slurry or abrasive in water directed at high velocity against the work pieces.

- Wetting Agent. A substance that reduces the surface tension of a liquid, thereby causing it to spread more readily on a solid surface.

- Whiskers. Metallic filamentary growths, often microscopic, sometimes formed during electrodeposition and sometimes spontaneously during storage or service after finishing.

- Work. In plating, the material being plated or otherwise finished.

View Our Services

Metal Plating Services

We specialize in gold, silver, copper, and electroless nickel (autocatalytic) precious metal plating services.

Learn More

Metal Coating Services

We offer premium chemical conversion coating when bonding and corrosion resistance is critical.

Learn More

Metal Passivation Services

Passivation is the process used to remove free iron and organic materials that may have been left on the surface.